9500 Dew Point Chilled Mirror Analyzer

The 9500 series SF6 analyzer is a high-precision, high-stability Dew Point Chilled Mirror Analyzer. The 9500 series include several models: 9500-E, 9500-A, 9500-L, 9500-V5, 9500-EPV5, 9500-V5MIX, and 9500-EPV5MIX, which can better meet SF6 gas testing needs in various scenarios.

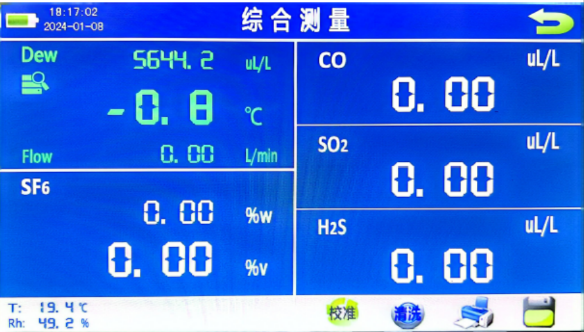

The 9500 series can measure multiple SF6 gas components, including moisture, purity, SO2, H2S, CO, and other decomposition products, depending on the selected model. The 9500-EPSF6 and 9500-EPV5 are two environmentally-friendly devices, allowing the measured gas to be compressed back into switchgear or external cylinders.

The 9500-V5MIX model is the latest integrated instrument designed for SF6/N2 mixed gas testing.

Features

l A variety of devices can provide solutions for different scenarios.

l Provide measurements of humidity, purity, and decomposition products

l Two methods for disposal of measured gases (no leakage)

Ø Directly compress the gas back into the test gas chamber

Ø Compress the gas into an external cylinder

l Test results can be printed directly

l Large-capacity lithium battery power supply

l Remote wireless online monitoring (by the end of 2026)

Classic application

l Humidity Calibration Standard Dew Point Chilled Mirror Analyzer

l Analyze the SF6 in high-pressure SF6 cylinders

l Analyze the SF6 in all electrical equipment filled with SF6 gas, including moisture, purity, SO2, H2S, and CO

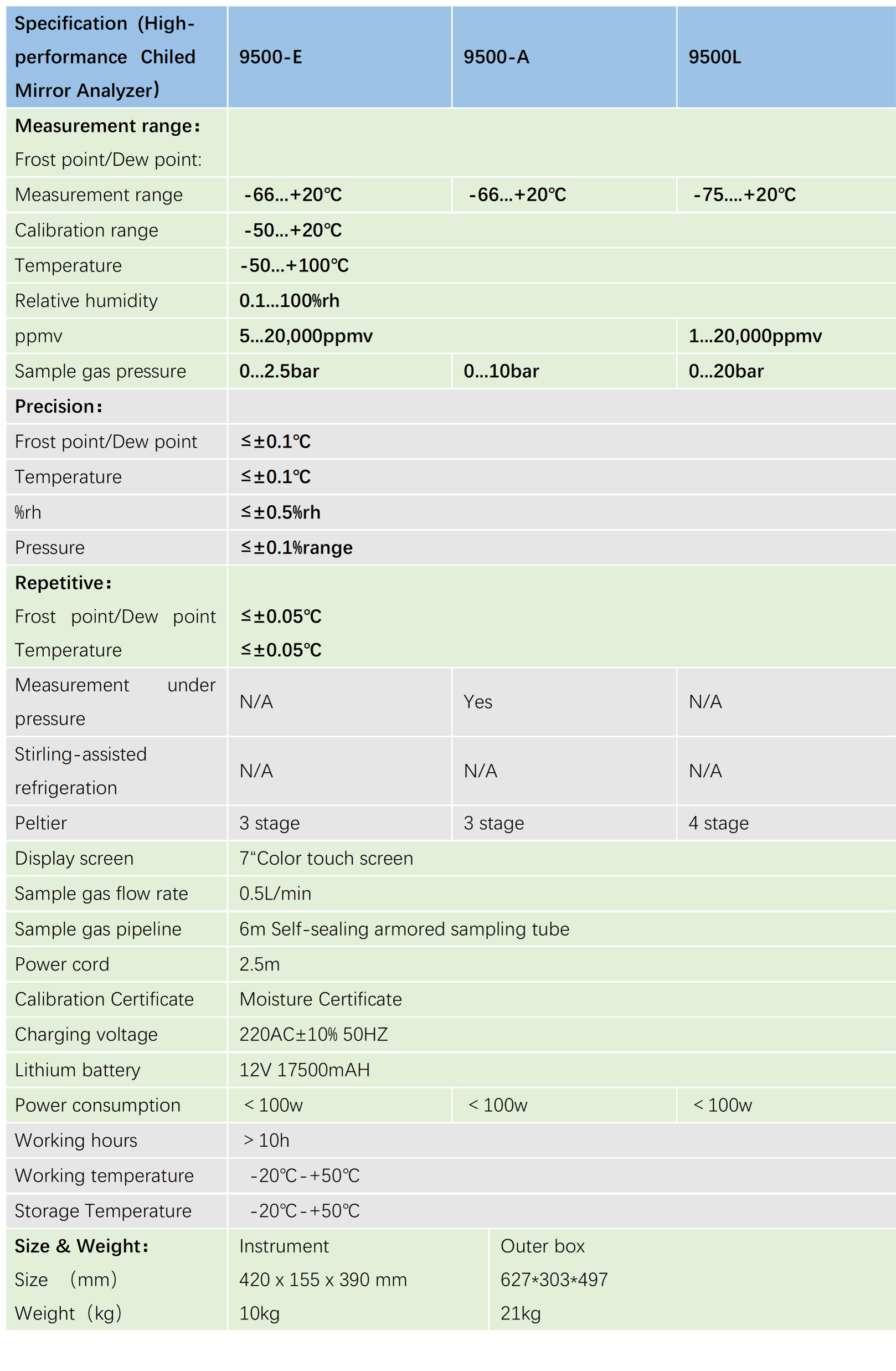

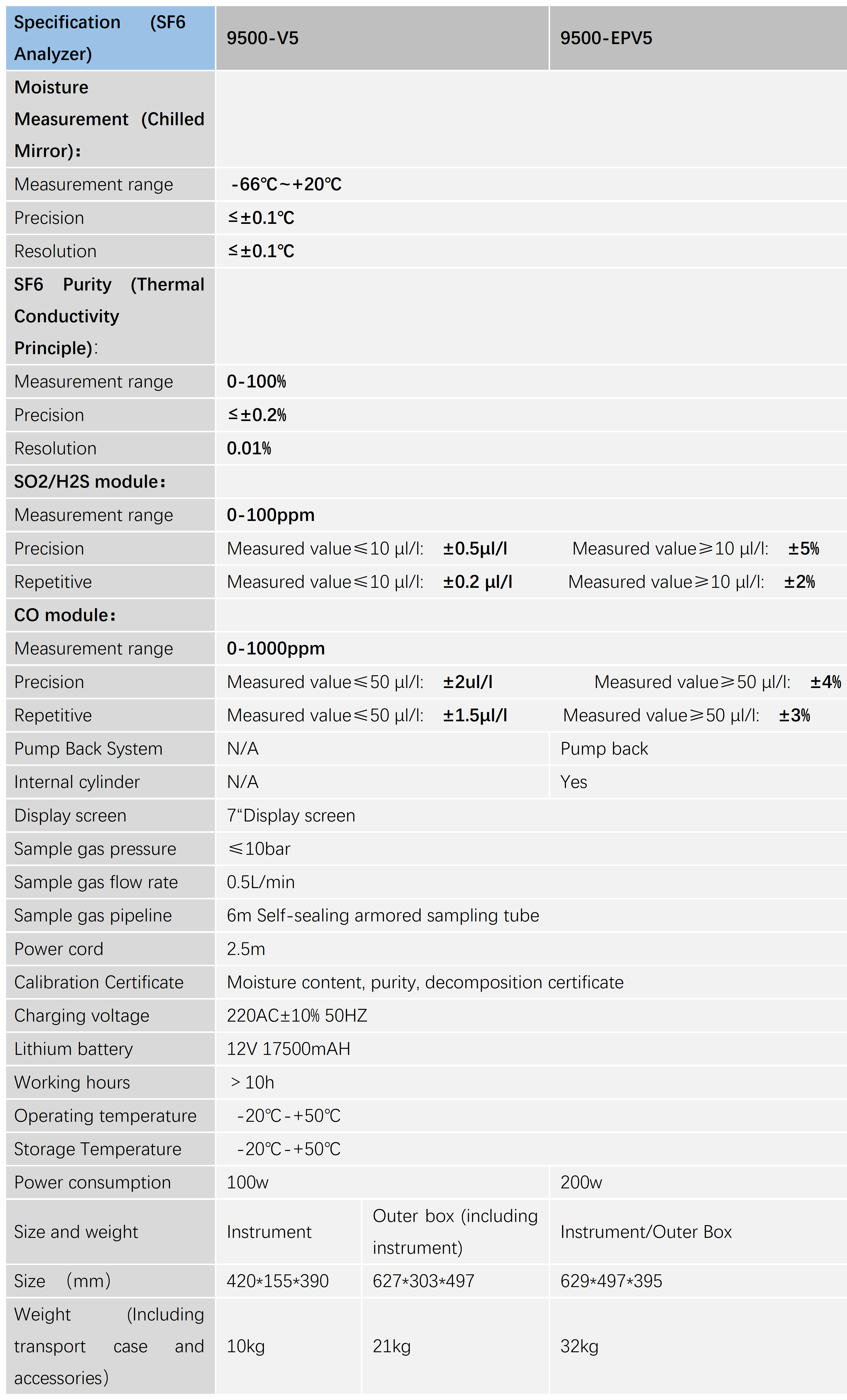

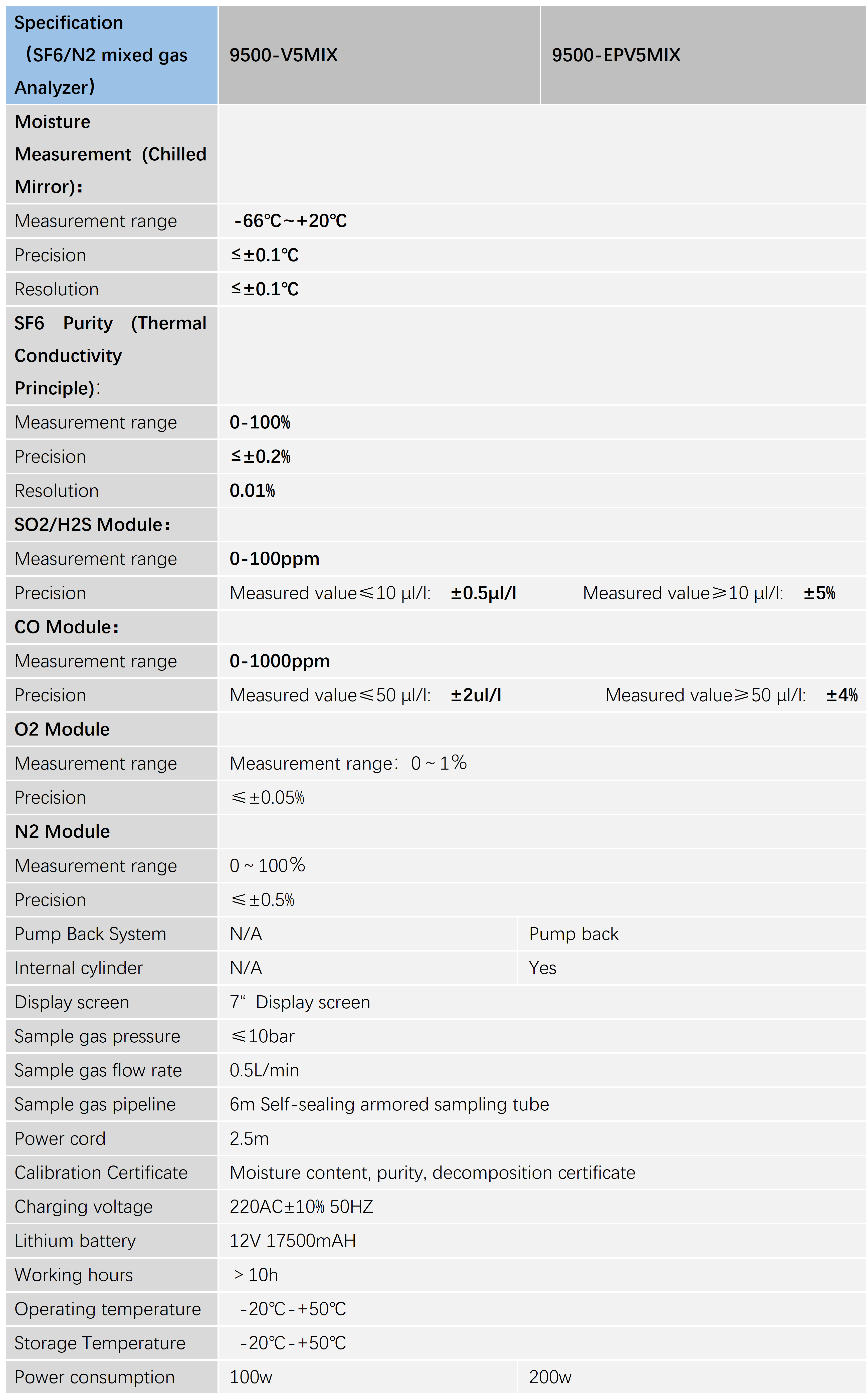

Technical specifications

More information

High accuracy and repeatability

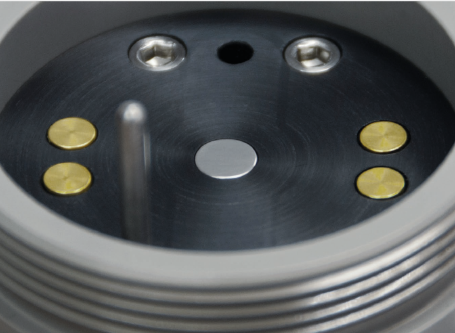

Chilled mirror technology is currently the most accurate and reliable method for measuring humidity. Water vapor in the gas is cooled onto a polished mirror surface to form a dew point, and then the temperature is measured. Since this dew point temperature is specific to the water vapor concentration, highly accurate results can be obtained without a humidity sensor.

Intuitive user interface

The measurement results are clearly displayed on a bright full-color touchscreen. The results are shown on the display for the user.

Ice point test calibration

At atmospheric pressure, the melting point of ice is always 0°C. The 9500 uses this fundamental value to immediately provide users with a calibration stability check through the ice point testing function. During the automatic test, the mirror is cooled below 0°C, causing water vapor in the air to condense and freeze on the mirror's surface. The mirror is then heated, and while observing the mirror, the user can simply press the button on the screen to confirm the ice melting point. The 9500 measures the temperature of the mirror at this point and displays a pass/fail indication on the screen. The test can be repeated as needed without affecting the instrument's performance.

Thermal conductivity purity detection module with temperature compensation

Changes in ambient temperature directly affect the temperature distribution of the measured gas, thereby altering the thermal conductivity of the mixed gas, which in turn causes variations in the output of the detection system and leads to measurement errors. On the other hand, changes in ambient temperature directly change the heat dissipation conditions of the measured gas, which also alters the sensor temperature at thermal equilibrium, thereby affecting the system output. Using the most advanced sensors based on the thermal conductivity principle with temperature compensation makes the measurements more accurate.

Decomposed Module of Anti-Cross-Interference Design

Using multiple electrochemical sensors to simultaneously measure a mixture of various target gases, when a sensor shows cross-sensitivity to a specific gas, it can affect detection accuracy. Built-in specific chemical filters can filter out interfering gases before they reach the sensing electrodes of the electrochemical sensors, thereby reducing interference from specific gases.